LIANG DAR

About Us

LIANG DAR

About Us

About Liang Dar

Precision, Quality, and Dedication

//////////////////////

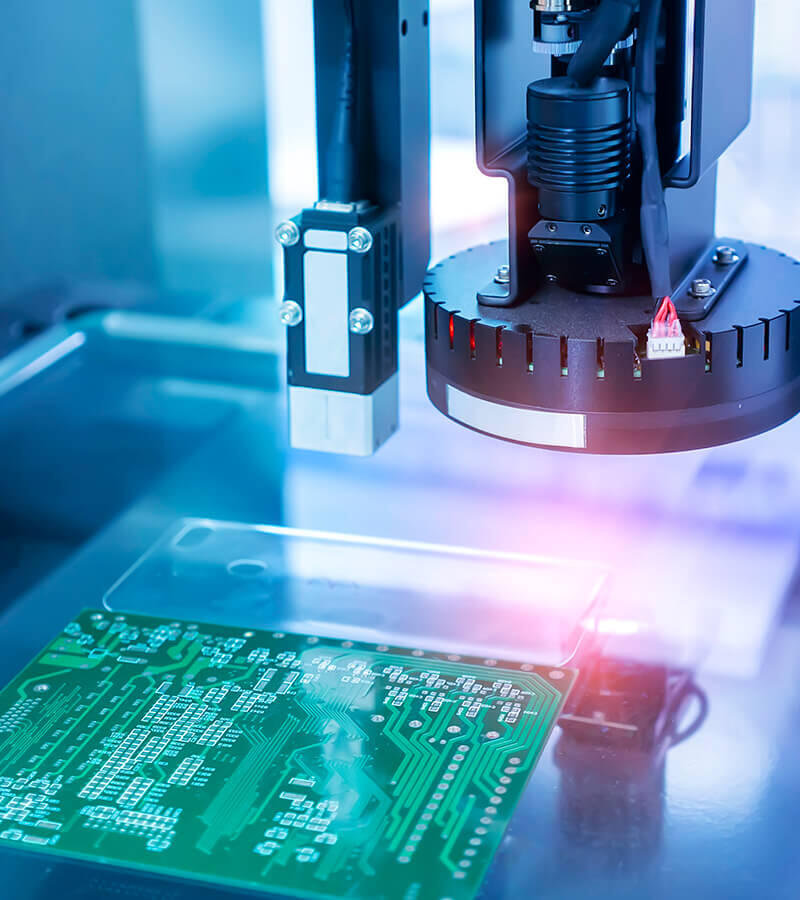

Liang Dar Technology Co., Ltd. (hereinafter referred to as "Liang Dar") is a printed circuit board (PCB) manufacturer founded in 1994. Based in Kaohsiung, Taiwan, the company provides full-process PCB manufacturing services. Liang Dar’s products are widely used across numerous fields, including lighting, automotive, industrial control systems, power supply, and consumer products.

With decades of experience in the industry, the founders of Liang Dar have been dedicating themselves to customer service, quality products and technological innovation since the creation of the company. Liang Dar continues to invest in talents and manufacturing equipment to provide customers with integrated PCB services based on efficient communication, swift delivery, quality products and competitive pricing. Liang Dar not only has a strong business team that is always ready to serve but also set up manufacturing facilities across Taiwan and other regions to meet customer needs. The company has more than 1,000 staff members and has obtained international quality certificates, such as ISO-14001 and IATF-16949.

Taiwan Professional PCB Manufacturer(Factory)

Liang Dar’s products and services are well-recognized across the international market. The company proudly serves customers around the world, including numerous world-renowned brands and electronic manufacturers. Liang Dar is equipped with a well-developed quality management system and internal product testing and validation process. With the most rigorous and dedicated attitude, we ensure that the quality of our products meets our customers’ requirements and international standards.SINCE 1994

Top 100 Printed Circuit Board Manufacturer

Pioneer in various fields of PCB

Full Process Production

Multiple Production plants

Close Relationship With Customer

10+ years of relationship with our main customers

Global Mindset

Diversified customer and production

innovation

Innovative Technologies & Flexible Manufacturing

//////////////////////

Technological innovation has always been the focus of Liang Dar. The company continues to put forward new solutions for PCB manufacturing and materials and develops new technologies and products to meet customer needs. Equipped with a professional and experienced R&D team, Liang Dar has been working with world-class electronic manufacturers in the PCB industry to develop new products that better satisfy market demands. In the face of global competition, we not only provide quality manufacturing services for single-sided, double-sided and multi-layer boards but also continue to develop and improve the manufacturing processes for PCB substrates of metal or other special materials. With a highly flexible production management model, we help our customers manufacture products of small, medium and large sizes in different quantities.

In the future, Liang Dar will continue to work on technological innovation and pursue excellent quality, providing customers with even better products and services. We will continue to explore new markets and fields as we strive to become the world's leading PCB manufacturer.

In the future, Liang Dar will continue to work on technological innovation and pursue excellent quality, providing customers with even better products and services. We will continue to explore new markets and fields as we strive to become the world's leading PCB manufacturer.

Liang Dar's DNA

Founded in 1994, with our deeply-rooted business culture, Liang Dar has been able to stand firm in the industry and gain customer trust with decades of experience.

Global Mindset

- Business wise: Aiming at developing global business opportunities

- Production wise: Provide various options in terms of production sites. Being able to integrate selected supply chain.

Relationship Maintenance

- Meet commitment made to customers

- Open communication with stakeholders

- Establish long-term and stable relationship with our supply chain

Customer Orientation

- Design proposal from customer’s perspective

- Work with our customer to shorten development cycle

- Diversified selections of material. Provide support in advance material preparation.

- Experienced quality and business service by our professionals

R&D and Production

- Diversified research & development in new products and processes

- Joint development of new technology and new process with customers

- Rigorous process control and management

- Provide production flexibility to meet customers’ demand

Sustainable Development

- Minimize environmental impacts generating by company's operation through energy saving, carbon emission reduction, efficient operation and so on

- Strive to provide a healthy and safe workplace for our employees

Competitive Advantages

Flexibility

Capable of accepting order from small to large quantity

Quality

Higher standard of quality to avoid reinspection

Prompt Response

Timely response to our valued customer by our diversified sales team

Production

Providing exceptional production capability to fulfill our customer’s needs

Information Technology

Prioritize digital transformation and information security

Global Market

- USA

- Chicago

- Michigan

- California

- Canada

- Mexico

- Brazil

- Europe

- Denmark

- Poland

- Netherlands

- France

- Germany

- Austria

- North-East Asia

- Taiwan

- China

- Japan

- South-East Asia

- Thailand

- Malaysia

- Singapore

- Indonesia

- Philippines

- South Asia

- India

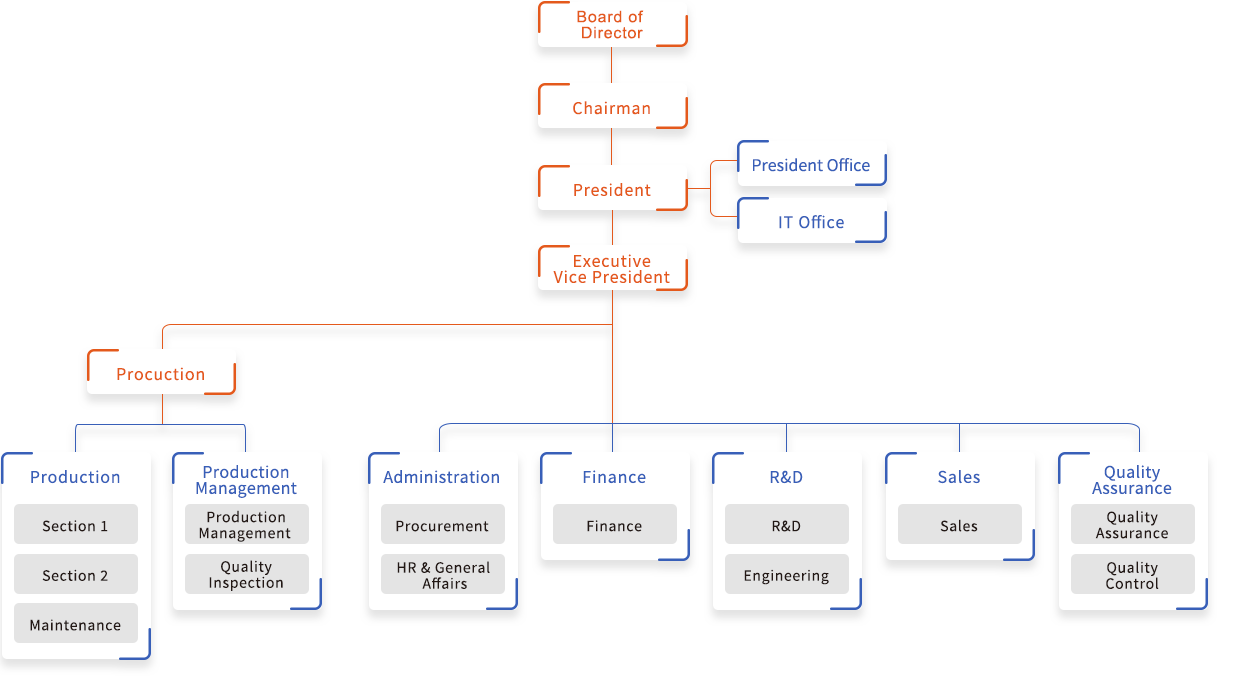

Organizational Chart

Modern business management philosophy is the foundation of Liang Dar. Our organizational structure is in line with the company’s development and demands and possesses management flexibility. The company’s ultimate goal is to create the highest value for our stakeholders.

- 1994

- Liang Dar was established

- 1997

- Liang Dar obtained ISO9002 certification

- 2001

- Liang Dar obtained QS9000 certification

- 2002

- Dongguan plant (Lianqiao) was established

- 2003

- Lianqiao obtained QS9000 certification

- 2004

- MCPCB by a well-known European lighting manufacturer was put into mass production

- Liang Dar successfully implemented ERP

- Lianqiao obtained ISO14001 and ISO9001:2000 certification

- 2005

- Group 10th anniversary

- Liang Dar obtained ISO14001:2004 certification

- 2006

- Second plant was launched by Liang Dar

- Liang Dar obtained TS16949:2002 certification

- Second plant was launched by Lianqiao

- Lianqiao obtained TS16949:2002 certification

- 2007

- Copper base and double-sided aluminum MCPCB were put into mass production

- Automotive LED MCPCB by well-known automotive makers were put into mass production

- Thick copper MCPCB for power supply unit was put into mass production

- Lianqiao obtained IECQ/QC080000 certification

- 2009

- Third plant was launched by Liang Dar

- Certified by a well-known Korean TV manufacturer

- Lianqiao began MCPCB mass production

- Lianqiao obtained Philips EICC certification

- 2010

- Lianqiao obtained BS OHSAS18001 certification

- 2013

- COB LED mirror aluminum MCPCB by a well-known European lighting manufacturer was put into mass production

- 2014

- Copper pedestal MCPCB for LED headlights by a well-known Japanese automotive makers was put into mass production

- 2015

- Third plant was launched by Lianqiao

- 2016

- The MCPCB process capability has been improved to 6.0mm thickness of copper and aluminum boards

- 2017

- Fourth plant was launched by Liang Dar

- Installed vertical continuous plating (VCP) equipment & alkaline and acidic vacuum etching lines

- Liang Dar obtained IATF16949 certification

- Liang Dar obtained GE SRG certification

- Lianqiao obtained IATF16949 certification

- 2018

- Lianqiao obtained GE SRG certification

- 2019

- Installed punching machine to expand capacity

- 2020

- Liang Dar successfully implemented Business Process Management (BPM)

- 2021

- Installed CCD LED double-sided exposure machine (soldermask) and CCD drilling machine to achieve the relative position tolerance within ±0.05mm

- Liang Dar launched Taoyuan plant

- Lianqiao obtained AEO certification from China customs

- 2022

- 14oz. thick copper MCPCB for electric motorcycle and heavy machinery was put into mass production

- 2023

- Installed Dedicated Arm Type Auto Test System

- 2024

- Installed Flying Probe Tester(Kelvin Four-terminal Sensing) and Legend Inkjet Printing System